Walkways & Handrails

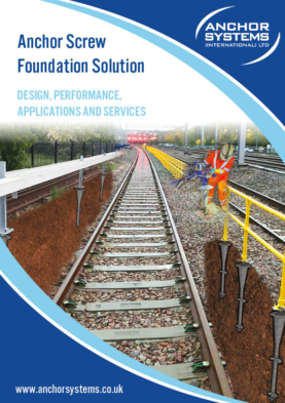

Walkways and handrail systems play a crucial role in maintaining safety across the rail network, providing stable, secure access routes for both emergency evacuation and routine trackside maintenance. These systems are frequently required alongside rail lines, on embankments, across uneven ground, and in locations where traditional construction is impractical or disruptive.

Anchor Systems supports these installations by supplying anchoring solutions designed around our Anchor Screws. Working alongside leading walkway and troughing manufacturers such as TroTread and Cubis, we deliver complete, engineered foundations that support GRP walkway trays, handrails, and elevated cable routes. Anchors are typically installed at 3-metre centres, with custom interface plates and support trays forming a robust, modular system.

Key Advantages

Traditional walkway construction often relies on sheet piling or concrete foundations, which can introduce significant cost, disruption, and safety complexity. Common challenges include:

High installation costs due to heavy plant, excavation, and deep piling

Extended possession requirements for works close to the running line

Limited adaptability on steep, uneven, or restricted sites

High environmental impact, heavy spoil removal, and reinstatement works

Anchor Systems’ screw-in foundations overcome these issues by offering:

Rapid installation – up to 70–80 metres of walkway can be completed per shift

Minimal disruption – often installed without track closures or heavy machinery

Lower overall project costs – no concrete, no sheet piling, no reinstatement

Long design life – Anchor Screws typically exceed 50+ years

Adaptability – easily configured to suit embankments, cuttings, complex ground, or non-standard tray spacing

In one comparative project, a conventional sheet-piled design exceeded £3 million, whereas the screw-anchored walkway alternative delivered a similar solution at a fraction of the cost.

Which Products Are Used for This Application

Typical components used in walkway and handrail installations include:

Anchor Screws (AS-1500 to AS-1900): Standard 1.5–1.9 m anchors providing lateral and vertical stability.

Interface Plates: Large steel plates customised for the required tray spacing (commonly 3 m).

Support Trays: GRP troughing or walkway support trays (TroTread, Cubis, or bespoke systems).

Handrail Assemblies: GRP or galvanised steel handrails depending on site requirements and environmental exposure.

All elements can be adapted for temporary or permanent installations and configured to meet load, spacing, or geometry requirements.

Types of This Application We Can Work With

Safe cess extensions

Emergency evacuation routes

Trackside maintenance walkways

Elevated walkway or cable-trough systems

Combined walkway and cable-management routes

Walkway solutions for embankments, cuttings, station approaches, and bridges

These systems are suitable for both permanent infrastructure and temporary access during maintenance programmes.

FAQs

01

Do walkway installations require a track closure?

Not always. Many installations can be completed from the cess without a full possession, provided adequate safe working space is available.

02

What is the design life of the system?

Anchor Screws typically achieve a 75-year design life, while GRP components offer between 25 and 50 years depending on exposure and use.

03

What happens if ground conditions are poor?

Where ground is soft or variable, anchor spacing can be reduced or shorter tray segments used to maintain uniform support and stability.

Get to know more about the product

Our Anchor Screw brochure provides full technical specifications, loading capacities, installation guidance, and project examples to support your planning and design process.

Explore Anchor Screw Foundations

Our walkway and handrail foundations are built on the strength, speed, and reliability of our Anchor Screw systems. If you’re planning a rail access route, cess extension, or elevated walkway installation, explore how our Anchor Screws can support your project with fast installation, long design life, and minimal disruption.